About Me...

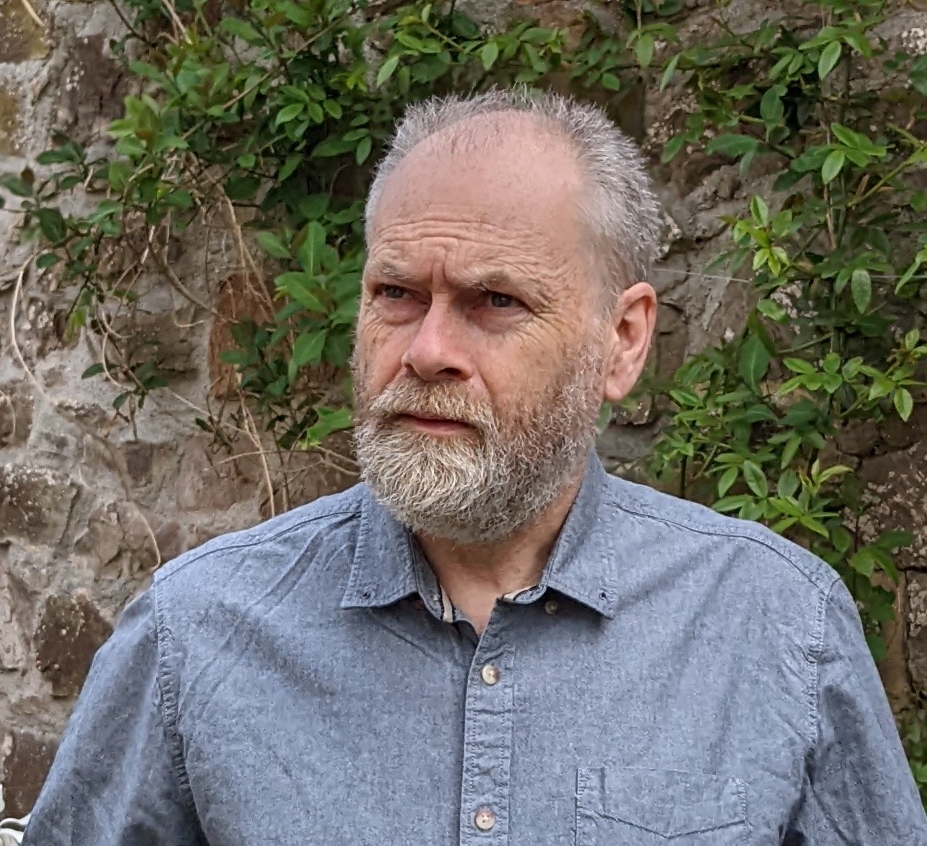

Dr Patrick 'Paddy' Hook

I live in deepest, darkest mid-Devon with my wife, Claire and our two beloved dogs, Rufus and Limone (pronounced 'Limony'). We also have two rag doll cats which do their best to out-do each other in the grumpiness stakes....

Although I was born in East Africa, I grew up in Devon, where I also went to school, college and university.

At school I was told that I wasn't academic, so I only paid attention to the stuff that interested me. I didn't realise at the time that it was an institution which mainly existed to educate the sons of the area's business elite - the rest of us were there simply to make up numbers. Consequently, I left with the bare minimum of qualifications.

It was only when I was in my mid-20s - while I was working as a motorcycle mechanic and MOT tester in High Wycombe, that I caught up. At the weekends I worked (unpaid) for the boss on his racing sidecar. In my desperate desire to learn how to build better racing motorcycles I signed up to the local technical college where I discovered that I was actually quite a good scholar. It turned out that when my brain was turned on to something it liked, it seemed to work quite well! I found myself top in everything except calculus, which I'd previously developed a bit of a mental block over. That annoyed me, so I sat down with a stack of maths books which my mates had given me until I found one that spoke in a language I could understand - and then devoured it. When it came to exam time, I got a Merit.

I then changed jobs, becoming a Test Engineer at The British Internal Combustion Engine Research Institute (BICERI) in Slough for two years. There, we ran (mostly) automotive engines on dyno test beds. These screamed away 24 hours a day, seven days a week, only being shut down for five-hourly maintenance checks.

After that, I went to Nicholson McLaren Engines in Hounslow, right under the flight path for Heathrow. There, I spent two years building a computerised test bed to take Formula 1/F3000/Group C Cosworth V8 engines. I went from there to Los Angeles to work in 'an exotic motorcycle studio' where we did all manner of high-end stuff like MV Agustas, Laverdas, Ducatis, etc. That lasted until the boss failed to sort the paperwork for me to work there permanently, so I returned to the UK.

For a while, I ran my own business focussing on racing cylinder heads. As an illustration of the sort of stuff I did back then, here's a little anecdote:

A mate of mine - Ken Cooper, ran a GSX1100-based drag bike out of his shop in Hounslow. One day, he called me up and asked if I'd go over and check through his engine, as it simply wasn't performing. He'd spent huge sums on all the right stuff - cams, big bore, carbs, headwork, etc. but it just wasn't producing the times. He'd stripped the whole thing, and had it laid out carefully on a big bench for me. I examined each piece in turn before saying to him 'Everything here is spot-on - except the head - that's bloody awful'. He was aghast, as he'd spent a huge amount of money having it ported by supposedly the best man in the country. The bloke had even engraved his name on it! I told him that he was very lucky - although the porting was bad, the head was redeemable. This was on a Friday - I took it home with me, worked on it over the weekend, and returned it on the Monday. The following weekend he took the European record in his class!

Doing favours for mates didn't pay the bills though, so I went for an interview at Pi Research, a company that did the on-board computers for things like F1 cars. I didn't fit in though - I don't easily suffer the games of office politics, something that sadly was rife there. I did work my socks off, however, and loved both the on-board computers and working with the teams in the pit lane. The mechanics there said that they really appreciated my lack of technical BS and that all the other computer people they saw at the tracks who turned up to push their wares were arrogant and out of touch with what was needed in the real world.

It wasn't long before I started looking at ways to make the car systems work on a motorcycle. This wasn't straightforward as the black boxes measured 'lateral G' (i.e. corner forces) and then used this data to work out what the circuit looked like. By using an infra red beacon on the start/finish straight, it could then superimpose information from various laps onto the same graph. So, for instance, you could see whether one lap was better than another, for whichever channel you were interested in - speed, suspension behaviour, or whatever.

This doesn't work on a bike though, as the corner forces are resolved through the vertical centreline by it banking over in a turn. By taking the internal accelerometer out and re-positioning it, however, I could get the computer to determine that it was going through a corner. I then implemented a simple look-up table system for each track - all I had to do was tell it that Turn 1 was left, Turn 2 was right, and so on, and it worked perfectly, working out the shape of the track and allowing me to work from then on exactly as though it was in an F1 car.

While all this was fine in theory, I still needed to prove it out properly on the tracks. At this stage I managed to get Steve Parrish's 'phone number - he was Team Manager for the Loctite Yamaha Superbike Team, so I called him up and basically said 'If you let me put my computers on your bikes, you'll get free access to half a million pounds-worth of kit'. Steve being Steve, he wasn't slow to see the possibilities, so he invited me over to install a system on one of the bikes. We then went to Snetterton for a test day, where the initially very sceptical chief mechanic gave it close scrutiny. Fortunately, he was blown away by it, and before I knew it I was overseeing the data for two riders - Terry Rymer and Rob McElnea at many of the big 1991 races at places like Brands Hatch, Mallory Park and so on.

Shortly after, we went to the Isle of Man TT - I drove one of the Loctite Yamaha vans over and then helped set everything up. Steve Parrish wasn't there though - he was off in Europe racing his Mercedes super-truck. Instead, Rob McElnea stood in as Team Manager, with Steve Hislop as one of our riders. For the first week, everything went swimmingly well, but then my managers back at base started interfering, stating that I was becoming too close to Loctite Yamaha, and that because of it, no-one else would want to buy the equipment.

I explained my dilemma to Steve Parrish, and he kindly spoke to Barry Symmons, Team Manager for the John Player Norton Team. Barry, being another astute man, could see the advantages of having the computers on his bikes, so he welcomed me with open arms. I therefore had the strange experience of working with two different teams at the same time. Our riders were Robert Dunlop and Trevor Nation.

I'd not long been back on the mainland when I got a call from Garry Taylor, Team Manager for the Lucky Strike Suzuki GP Team. They needed a computer system, and Barry had told them how good our stuff was. A few days later, I was in the Edenbridge team base, showing it all off. Again, they'd seen it all before, and heard all the fantastic claims made by other people, but the fact that I'd made it work at the TT - possibly the hardest race for any high-tech kit to survive, worked in my favour. They agreed to fit one bike out and a few days later, we did a test at the Donington circuit.

The test went extremely well, and before the day was out, Garry asked me to go for a walk up the pit lane with him. He basically said to me 'We want to buy two complete systems for the bikes, but we're only prepared to do so if you'll come too. What are you going to cost?'. Luckily, I'd done my homework:

1. I knew that I was the only person in the world who knew how to run the computers on a bike.

2. I knew that their star rider - Kevin Schwantz, had refused to sign up for the following season if he didn't have computers and a computer guy.

3. I knew that there were only two other data acquisition systems that were suitable for a GP bike. One was Honda's own - and they were so secretive that they wouldn't even allow their non-Japanese mechanics to see the results. The other belonged to Yamaha, and had been developed by Tom O'Kane, the Marlborough Yamaha computer specialist.

In other words, there were no other computers, and no-one else available to operate them. Consequently, I was able to negotiate 'A Good Deal'...

My first race with Lucky Strike Suzuki was a strange one - I'd helped the Norton team prep Ron Haslam's bike for the Superbike race, which was being held on the same day as the GP, and then done the same for Kevin Schwantz. Ronnie won his race, and then Kevin won the GP. Two wins in a day for me! I was leaning over the computer after the race when someone slapped me very heavily across the back - before I could spin round and punch the culprit out, I heard Kevin yell 'Thanks, Mate!'. OK - I'll let you get away with that one!

I then spent the rest of the 1991, 1992 and most of the 1993 seasons with the team, travelling all over the planet and getting thoroughly fed up with airport check-in queues, hotel check-in queues, etc. What made matters a lot more difficult is that the mechanics in the team had never worked with computers before, and hated having all these black boxes and wires in their way. I'd not been there long when just as we'd finished after a long day's work at the Shah Alam circuit in Malaysia, one of them snipped a cable tie - only it wasn't a cable tie, it was one of the main harnesses for the computer system. At that stage, we didn't have a spare harness, so I had no choice but to repair it. The company would have had a fit - there's no way that they'd have allowed a field repair, but we had no choice. So I had to sit there and tease all these micro wires out and find a way to solder them back together. And all the time, all I got was constant abuse from the mechanics who were only interested in getting to the bar. Somehow, it was all my fault...

While I was with the team, I got very involved with chassis geometry - I wrote an analysis program - some 200,000 lines long, which could take all the various chassis settings and then produce a very detailed report as to things like the resultant rake, trail, crankshaft centreline to rear wheel spindle distance, anti-squat ratio, etc. This was way ahead of its time, and the Japanese staff were completely befuddled by it. Their secret R&D division tried to produce their own version - with every bit of help I could give them, but in the end they gave up as they simply couldn't get their heads around it.

The consequence of having a rigorous scientific way of monitoring what we were doing, was that over the 92/93 winter testing season we took the lucklustre 1992 bike and made it work. At the opening GP - at the Eastern Creek circuit (which had previously been our worst venue), Kevin qualified on pole. When the flag dropped, however, the bike bogged and he got away in 18th place. By the end of Lap 1 he was 10th, and within a couple more he was at the front playing games with Wayne Rainey. For the first time we had a bike that would out-turn the Yamaha. Needless to say, we won the race.

Sadly, although Kevin went on to win the 500cc World Championship in 1993, my relationship with the team had spiralled out of control. I was getting grief from all directions - I won't say any more than that it all stemmed from the fact that the team had never had a computer man before. They thought that all they needed if they kicked me out was a laptop - how wrong they were. I left, and over the next two years the team's performance nose-dived so much that they couldn't even have won the Privateer's Cup.

1994 was an odd one for me. I'd managed to get myself banned for speeding in my Cosworth (no surprises there!), so I decided to burn my energy in the gym, going six or seven days a week. It didn't hurt that the place was teeming with pretty women! I also put a lot of time into preparing my Harley hillclimber. With my licence back, I hammered my Fireblade all over the place, including taking a trip down to the Pyrenees. I few days later I suffered a 'Michelin high-side' at the Shelsley Walsh hillclimb. This was where the rear tyre slid going around a corner, then bit really hard, then flipped me over the high side of the bike, chucking me into a bank which terminated with a steel gate. The medics said that if I hadn't been wearing a back protector, I'd have split in two. I was in a mess - the bike was upside-down a few yards above me on the steep hill, with the electric fuel pump still running. As a result, it was pumping fuel back down and onto me - the only problem was that the switch lever had been broken off, so it wasn't until one of the other riders got there (thanks, Phred!) that they managed to sort it out.

To cut a long story short, I had a long hospital operation where I nearly died from loss of body temperature due to loss of blood. I woke up vomiting into an oxygen mask, wrapped in a space blanket intended to stop any further heat loss. There were pipes coming out of me all over the place, and as I couldn't move my arms, I was on the point of drowning in my own sick. Not a nice way to wake up! Luckily, a nurse spotted my predicament - but she simply emptied the vomit out and put the mask back. It stank, so I eventually managed to nudge it off so that I could get some fresh air. Unfortunately, she saw this, and just put it back. And so on...

Amazingly, I did a lap of the block where I lived eight weeks after the crash. I had tears running down my face from the pain, but a smile from ear to ear - I was a whole man again!

Whilst going through the long and slow recovery process, I decided to make a big change in my life, and went to study an Honours Degree in Computer Science at the University of Exeter. It was only a mile from my house, so it didn't take me long to get there on the 'Blade. In order to pay my bills I also took a job teaching motorcycle electrical theory & practice at what was then called Tiverton College (now Petroc).

I finished the degree in 1998 - I worked hard at it, and was therefore delighted to find that I'd been awarded a First Class Honours Degree - and then a couple of weeks later this was followed by a 'Dean's Commendation'. By this time I'd signed up to do a PhD over in the engineering department researching negative Poisson's Ratio materials (things that get fatter when you stretch them). That took a further five years, and I came out as 'Dr Paddy'. I did loads of over things during this time, including buying the Ferrari Dino (even though it was a pile of rust it still cleared me out for a couple of years), working in the Euopean Super-Truck Championships, firstly for DAF (the drivers were Alain Ferté and Gerd Korber) and then for CEPSA-Caterpillar (the driver there was Antonio Albacete). Antonio and I won the first race at Jarama and were on the podium at almost every event of the season. I also moved house from the centre of Exeter to a village in the middle of nowhere - because it had loads of outbuildings.

In 2003, I went to the Ferrari UK Sportscar Team (Team Veloqx), based in Brackley which competed in the NGT class in the European Championship. My job there was to race engineer a third car - they already had two, but after a few races decided that they wanted another one. Officially, it was out there to help influence the race results - that is, if 'my' car finished behind the other two, but ahead of the competition, then it would help our team's overall position. I'm not sure it was as simple as that, but that's another story. Anyway - there wasn't the budget to buy another car, so I was given some mechanics and told to build one out of the scrap pile. We didn't make ourselves popular with the rest of the team though - at the big Donington race - with Ivan Capelli and Guy Smith alternately at the wheel, our car was consistently faster than the other two. We could easily have won the event, but that wouldn't have helped the team's championship position placings, so we were told to bring the car in about five times, despite there being nothing wrong with it.

Later that year and with my doctorate finally in place, I was persuaded to form a spin-out company with the university to commercialise my research work. This went well for several years, although after the banking crash we we unable to raise any further investment money just at the time that we badly needed it. As we couldn't get funding anywhere, I worked like fury on other jobs to meet the company's financial committments. As an example, one year - on top of running the business, I also wrote ten books and did all of the photography for three of them (natural history subjects). I ended the year looking like a ghost.

Sadly, the company folded after some bitter shareholder in-fighting, to which I was a helpless bystander. Since then, I've continued to do all manner of things to keep the wolf from the door, including medical research, defence-related R&D work, book and magazine writing, and even programming the computers for giant crop sprayers! And, of course, getting my hands dirty on a daily basis working on everything from Land Rovers to the Aston Martin.